SURAJ RECYCLING PVT. LTD. serves industry (with the help of its sister concerns SURAJ BRASS CASTING, SURAJ IMPEX, JAPHNA BRASS CASTING) like: Brass Building Fitting Hardware, Brass Sanitary Pipe Fitting, Brass Electrical Fitting, Brass Auto Fittings, Brass Fasteners, Brass Oil/Gas/Pneumatic Fittings, Brass Nuts/Bolts/Rivets, Brass Extruded Rods, Brass Ingots, Brass Granules and Brass Components made from Casting, Extrusion and Forging.

SURAJ RECYCLING PVT. LTD. is known for it's prompt response; is always eager to serve it's customers in better ways. We always apply new ideas to improve our quality and offer attractive packaging. Our timely shipments enable us to avoid any types of Delivery time problems. We are very strict about timings given to us by our customers.

Brass is an alloy of copper and zinc. It has been used since ancient times in decorative crafts because of its rich color. Basically the copper content of brass ranges between 60% - 70% in components used in Engineering, Electric, Building Fittings, Compression Fittings & Bathroom Fitting industry. The higher the copper content, the more golden will be the brass.

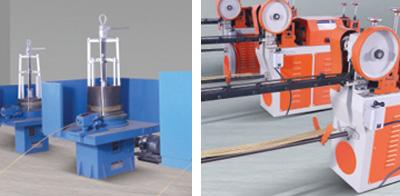

There are two main methods of brass casting that SURAJ RECYCLING PVT. LTD. uses, Die Casting and Sand Casting. Occasionally a third method called Wax is also used for parts. In all cases, brass castings are heavier than sheet brass and result in a virtually indestructible product. The caveat to brass castings is: Unless quality alloys of high purities are used and proper procedures for finishing and cleaning are employed, the Finish and Strength will not be durable.

Involves hand pouring of melted brass in a sand mold. It is intensely laborious and more than other forms of castings requires the need for high quality material. Sand castings are produced worldwide. In many underdeveloped countries, sand castings are made from scrap material and are of inferior quality. SURAJ RECYCLING PVT. LTD. castings that are produced using the sand casting method are cast in very fine sand with high-grade alloy in modern facilities and finished to exacting standards.

Produced under pressure in steel molds. Dies are very expensive but produce a precise casting. Quality of these castings is further enhanced if the melted metal is a virgin alloy as opposed to scrap. SURAJ RECYCLING PVT. LTD. uses virgin metals. When the casting is ready for turning we remove all surface blenishes such as chill marks with a fine sanding operation before we proceed to polish our brass.

This method is employed for great detail. Wax casting allows for shapes with undercuts that cannot be produced by other methods. Artists use this method to produce statuary. SURAJ RECYCLING PVT. LTD., uses this process only for a few highly detailed components. Unfortunately, lost wax casting is not ideal for polished finishes.

Brass billet are cast from die casting and are heat-treated to 850°F (between solid and liquid) and then pushed in the Extruder press from oxygen free rods & sections. Brass has a small amount of lead compared to sand casting and wax casting, mixed into the copper and zinc alloy to ease its flow through the extrusion machine. A component made from extruded brass has a better quality of strength and it is used in mainly Electric & Compression Fitting. SURAJ RECYCLING PVT. LTD. , uses Copper and Zinc to get brass that has a ratio of 70% copper and 30% zinc alloy, which is mainly often supplied on coils to make brass fasteners.

A stamping process in which brass rod is heated to a plastic state (between solid and liquid) and then stamped to final size. The process produces extremely high, quality and density. It is used especially for components with a broad smooth surface. We heat-treat the components to a temperature of 850°F taking several hours. This heat treatment removes all of the internal stress in the brass so that the components will not get fractured over a period of time. Many products on the market are made of alloys with lower copper content and are not heat-treated for stress relief. These fixtures may get fractured after a period of time.